01/19/07 – Starting the

transmission mount

last night's progress...

Cut the rest of the tunnel out

(another 1" from the

rear)1 and

was able to

bolt up the transmission. It fits nicely, there is no need to remove or

even

move the engine to access the transmission bolts... That's a great

feature. Especially

for anyone who has ever tried to change the transmission on a 300ZX2...

I made a temporary transmission mount

out of this prybar 3:

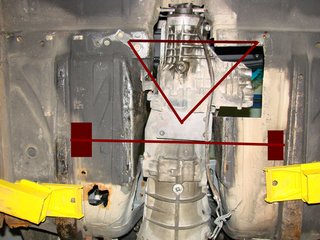

Here are a few shots of the

transmission in the car:

Next, I began planning a transmission

mount. The first step

was to make bolting plates. You can see the two I made here:

The main transmission bolting plate

is made from 7GA Mild

steel. You can see it bolted to the rubber transmission mount. We

decided on

keeping the stock rubber trans mount, despite the fact that we are

using solid

engine mounts. Need to have some compliance somewhere!4

The other bolting plate picks up the

two bolts for the stock

transmission mount. Notice the distance from the rubber trans mount to

the

stock location. Since the transmission utilizes the rubber mount,

simply

joining the rubber mount to the stock location would result in a point

loaded

cantilever beam. The chassis is not meant to maintain such loading

especially

at a point that has already been compromised by tunnel modifications,

so an

alternate solution, or a dual cantilever beam, must be incorporated.

As I mentioned, since so much

material was removed from the

tunnel, a support brace would be desired. This brace was to be located

midway

down the tunnel, underneath the transmission.

Since the forward face of the rubber

mount on the

transmission is about midway back on the tunnel, it was decided that a

transmission mount/chassis brace "subframe" could be constructed.

Bolting plates will be welded to the chassis floor, then the

"subframe" will be bolted to that.

Here is an artist's rendition of the proposed solution:

The transmission mount was fairly easy. It should also provide extra support, as it ties nearly into the main frame rails… It’s currently rusting away in a storage bin at Innovative Tuning…

(1) I think I wound up eventually removing another 2”

(2) The worst transmission job I ever had to do

(3) It’s funny that I took the time to circle it…

(4) I’ve been told that a soft transmission mount coupled with hard (solid) engine mounts gives a fairly vibration free ride… We’ll see I guess…